TOP DOWN RECONDITIONING

If you want the same high quality as in a new machine, but at a more affordable price, then a reconditioned machine might be the solution for you. We have a large range of reconditioned machines.

The reconditioning of each machine consists of:

- Cleaning with professional tools and materials.

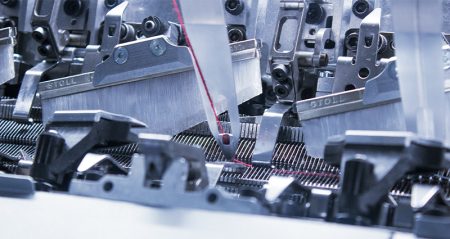

- Reconditioning of needlebeds.

- Reconditioning of camboxes with stitchmotors, magnets and camparts.

- Reconditioning of takedownrollers, belts, motors and mechanism.

- Reconditioning of yarncarriers and yarntensions.

- Checking electronic cards, electric, fans, battery, monitor and keyboard.

- Checking / reconditioning main and racking motor.

- Testing the machine in full working order.

- Adjusting stitch quality cams and other settings.

- Small set of spareparts, books and software included for first operation.

Reconditioning Machines will be prepared for transport with great care:

- Sprayed with oil and all metal parts greased.

- Covered with oilpaper and plastic.

- Packed and secured on wooden pallet or box.

- Or secured on truck with strapping belts and wood.

Aftersales:

- Machines will be delivered with 6 months guarantee.

- We can take care of installation and instruction wherever you are by our own experienced people.

- We can supply original spare-parts all over the world.

Please check our machine list to see our actual stock.